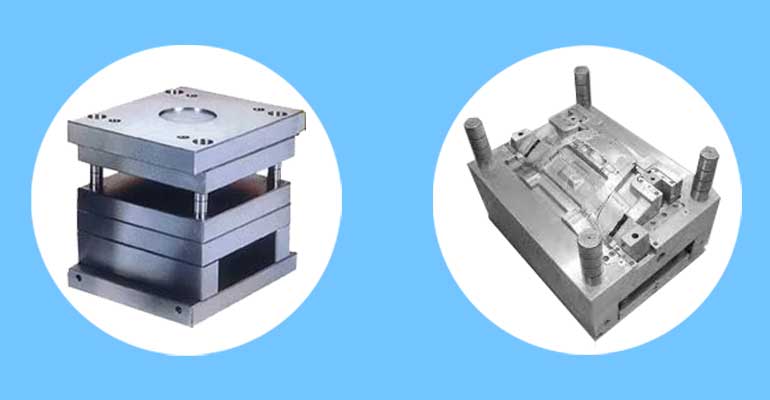

Pressure Die Casting Mould Base

A base for Pressure Die Casting is the foundational component used in the die casting picture to shape molten metal into particular forms. It offers structural support and alignment for the die-casting mould. It is composed of two halves: one is the cavity, and the other is the core. The mould base guarantees stability, precision and durability during the casting procedure.

At Precious Enterprises, one of the most renowned aluminium die-casting manufacturers in India, we specialise in creating superior quality mould bases tailored to meet the particular needs of different die-casting compilations.

Why is the quality of mould important in pressure die casting?

A high-quality Pressure Die Casting mould base guarantees uniform distribution of metal. It reads wear and tear and maintains high tolerance while portioning. Therefore, it helps minimize defects in the final products, including flash, porosity, or misalignment.

At Precious Entreprise, you are guaranteed exceptional strength and precision in the products because of the highly capable and diligent aluminium die-casting manufacturers in Pune, which further guarantee consistent casting results for our clients.

What are the materials used for manufacturing a mould base?

High-grade steel or other alloys are typically used to create Pressure Die Casting moulds because they can endure high temperatures and the rigours of the die-casting process. SKD61, P20 steel, and H13 tool steel are examples of everyday materials.

A number of variables, including the kind of metal being cast, the volume of production, and particular performance requirements, influence the choice of material. In order to satisfy the individual requirements of every project, our aluminium die-casting manufacturers in India provide mould bases constructed from carefully chosen materials, guaranteeing improved durability and thermal stability.

What are the fundamental components of a mould base?

Several parts make up a standard Pressure die-casting mould foundation, including the following.

● Support Plates: These plates are located below the cavity and core blocks and provide correct alignment and stability.

● Ejector Plates: After solidification, these allow the completed product to be smoothly ejected.

● Sprue Bush and Locating Rings: These parts help ensure that the molten metal flows into the mould properly and efficiently. Every component must be precisely engineered for the die casting process to go well. At Precious Enterprises, our experienced aluminium die-casting manufacturers in India optimise these elements as our top priority to improve mould performance.

Why choose Precious Enterprises?

Precious Enterprises has made a name for itself as a reliable partner in the pressure die-casting industry via its dedication to quality and innovation. The engineering of our mould bases is centred on accuracy, quality, and dependability. We provide the following.

●Mould base designs are made by the best aluminium die-casting manufacturers in Pune specifically tailored to your requirements.

●All-encompassing assistance and advice during the production and design phases.

●Premium goods are offered at affordable prices.

Are you prepared to improve your die casting processes with well-designed Pressure Die Casting mould bases? Speak with Precious Enterprises right now to discuss the details of your project. Our knowledgeable staff is available to offer unique solutions at affordable prices with outstanding quality. Reach out right now, and let us assist you in achieving exceptional outcomes!